Delve into the intricacies of SMT bonding operations through this comprehensive exploration, complete with a detailed video guide that demystifies the process, from setup to completion.

Introduction to SMT Bonding

Surface Mount Technology (SMT) is a method for mounting electronic components onto the surface of printed circuit boards (PCBs). This advanced technique has revolutionized the electronics manufacturing industry, offering increased efficiency, reduced costs, and improved performance. The SMT bonder operation video serves as an invaluable resource for both novices and seasoned professionals alike, providing a step-by-step visual guide to executing flawless bonding operations.

Preparation and Setup

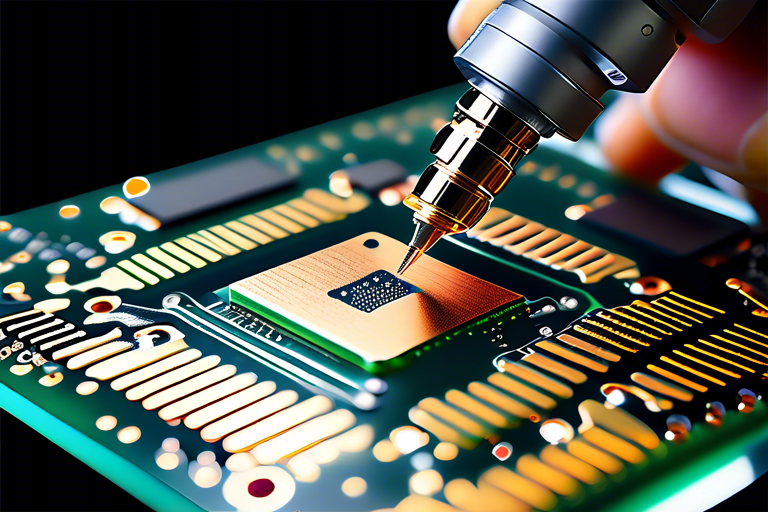

Before diving into the actual bonding process, it is crucial to prepare the workspace and equipment. The video begins by showcasing the necessary tools and materials, including the SMT bonder machine, solder paste, components, and a PCB. It then demonstrates the proper setup of the machine, emphasizing the importance of correct temperature settings and the alignment of the PCB and components. This meticulous preparation is key to achieving a successful bond and ensuring the longevity of the electronic device.

Posicionamento de componentes

The video highlights the importance of accurate component recognition, which is the first step in the SMT bonding process. It explains how the SMT bonder uses advanced vision systems to identify and position components accurately on the PCB. This technology is crucial for maintaining the precision and reliability of the final product.

Next, the video delves into the application of solder paste, a critical component in the bonding process. It demonstrates how to apply the right amount of paste to the designated areas on the PCB, ensuring a strong and secure bond. The video also touches on the importance of using high-quality paste to prevent defects and ensure optimal performance.

Bonding Process

With the preparation and setup complete, the video transitions into the actual bonding process. It illustrates how the SMT bonder applies heat to the solder paste, melting it and forming a secure bond between the component and the PCB. The video emphasizes the importance of controlling the temperature and duration of the heat application to prevent damage to the components or the PCB.

Quality Control and Inspection

After the bonding process, quality control and inspection are essential to ensure that the components are correctly placed and bonded. The video demonstrates various inspection techniques, including automated optical inspection (AOI) and X-ray inspection, which are used to detect any defects or misplacements. It also discusses the importance of these inspections in maintaining the integrity and performance of the final product.

In conclusion, the SMT bonder operation video is an essential tool for anyone involved in the electronics manufacturing industry. It provides a comprehensive and detailed guide to the SMT bonding process, from preparation to inspection, ensuring that viewers can execute these operations with precision and efficiency. By following the steps outlined in this video, professionals can enhance the quality and reliability of their electronic devices, staying ahead in a competitive market.