In the realm of manufacturing and electronics, the term ‘Small Bonder’ refers to an expert in the meticulous process of bonding small components. This article delves into the intricacies of micro assembly, exploring its significance, techniques, and applications in various industries.

Introduction to Micro Assembly

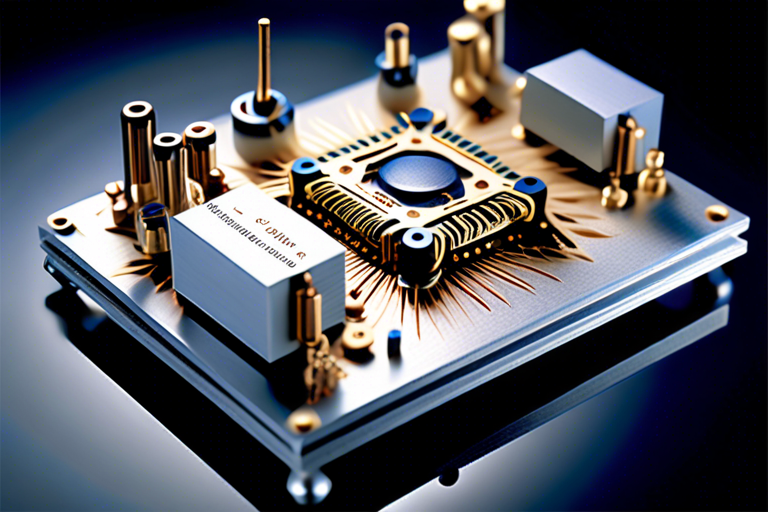

Micro assembly, a subset of precision engineering, is the process of joining small components with extreme accuracy. This field is crucial in the production of miniature electronic devices, where components are often measured in millimeters or even micrometers. The ‘Small Bonder’ is a professional who masters these techniques, ensuring that each connection is made with the utmost care to maintain the integrity and functionality of the final product.

Technological Advancements in Micro Assembly

With the rapid evolution of technology, the demand for smaller and more efficient devices has grown exponentially. This has led to significant advancements in micro assembly techniques. Small Bonders now have access to sophisticated tools and equipment that enable them to perform their tasks with unparalleled precision. The use of automated systems and robotics has streamlined the process, reducing human error and increasing efficiency.

One of the most significant advancements in micro assembly is the integration of automation and robotics. These systems can perform repetitive tasks with high accuracy, freeing up Small Bonders to focus on more complex aspects of the assembly process. The use of robots in micro assembly has not only improved the speed and quality of production but also opened up new possibilities for the design of intricate electronic components.

Laser bonding is another technological innovation that has revolutionized micro assembly. This method uses focused laser beams to create strong, precise bonds between components. It is particularly useful for applications where high heat or electrical conductivity is required, and it offers a clean, efficient alternative to traditional soldering methods.

Applications of Micro Assembly

Micro assembly techniques are applied across a wide range of industries, from consumer electronics to aerospace engineering. In the consumer electronics sector, Small Bonders are responsible for assembling components in smartphones, tablets, and wearable devices. In the aerospace industry, these techniques are critical for the assembly of sensitive navigation and communication systems in aircraft and satellites.

In the consumer electronics market, the demand for compact and powerful devices drives the need for advanced micro assembly techniques. Small Bonders must ensure that components are not only securely bonded but also designed to withstand the rigors of daily use. This includes withstanding drops, temperature fluctuations, and exposure to moisture.

Aerospace engineering relies heavily on micro assembly for the production of high-precision instruments. Small Bonders in this field must adhere to strict quality control standards to ensure the safety and reliability of the equipment. The stakes are high, as any failure in the assembly process could have catastrophic consequences.

In conclusion, the role of the Small Bonder is pivotal in the world of micro assembly. Their expertise and the application of advanced technologies are essential for the production of high-quality, reliable devices across various industries. As technology continues to evolve, the importance of precision and expertise in micro assembly will only grow, ensuring that the Small Bonder remains a vital figure in the manufacturing landscape.