BUYSMT:

Your reliable partner for used SMT machines

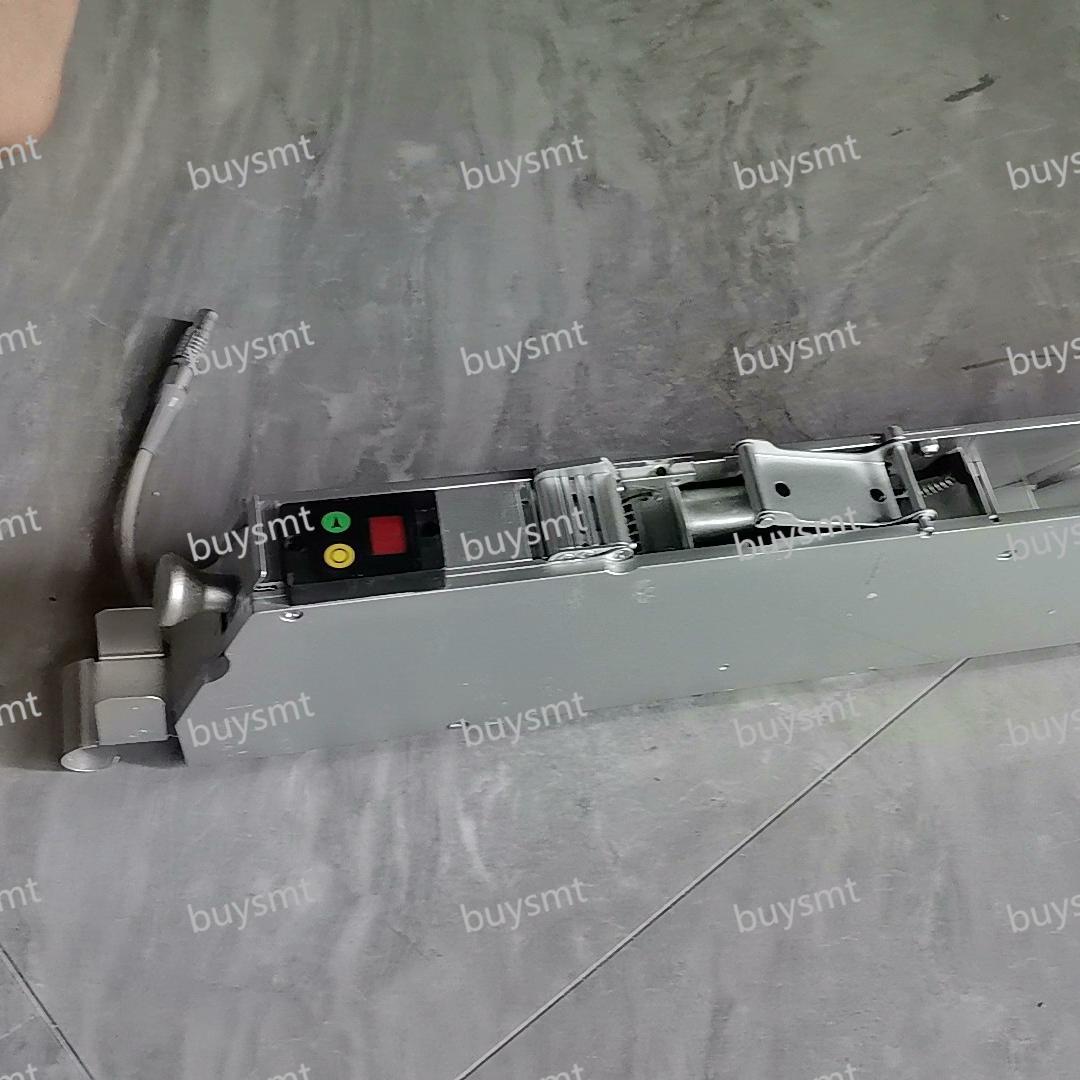

We offer a wide range of used SMT equipment from top brands, including high-speed pick-and-place machines, printers, and reflow ovens. Our equipment is thoroughly inspected and refurbished to ensure optimal performance and reliability, meeting the demands of high-volume production.

When you purchase used SMT equipment from us, you can rest assured that you’re backed by our comprehensive after-sales service and technical support.

Your Total SMT Equipment Supplier

With a wide selection of SMT machines and production lines, BUYSMT is your trusted partner for all your manufacturing needs.

SMT Machine

Looking for affordable and reliable SMT machines? BUYSMT offers a vast selection of new and used equipment from top manufacturers to meet your specific needs.

SMT Parts

Get the best deals on new and refurbished SMT parts. BUYSMT offers a vast inventory of components to suit any budget and application.

What our customers are saying

See what our customers are saying about their interaction with us to get a better understanding of our dedication.

BUYSMT has been a game-changer for our electronics manufacturing. Your wide range of high-quality used SMT machines and components has allowed us to optimize our production line without breaking the bank. Your reliability and commitment to customer satisfaction are unmatched in the industry.

Barbara Elliot

Hong Kong

We’ve been working with BUYSMT for years and have always been impressed with their exceptional customer service. Their team is knowledgeable, responsive, and always goes the extra mile to ensure our needs are met. We highly recommend BUYSMT to anyone in the market for used SMT equipment.

Jose Fuller

America

BUYSMT has provided us with the perfect solution for our budget-conscious project. Their used SMT equipment offers the same level of quality as new machines, at a fraction of the cost. We’ve been able to significantly reduce our production costs while maintaining high-quality standards

Marie Stewart

Deutschland

Check out latest products

New Arrivals

Find Your Product

Get Your Products

Inspect Your Products

Deliver Your Products

Purchasing SMT Product Has Never Been this Easy

Let BUYSMT be your trusted procurement partner. We source the highest quality products and guarantee efficient delivery, freeing you up to concentrate on expanding your operations.

Used SMT Machine & Parts Reclaiming

Make more room on your inventory and your budget as we purchase your surplus SMT machines and parts.

Drop Shipping Service

Enjoy fast purchasing with guaranteed safe and quick deliveries with our partner logistics companies bringing your products directly to your doorstep.

Machine Maintenance

You can rest assured about after-sales problems as we offer preventive maintenance services on the SMT machines upon request.

Technical Support

Equipped with expert technicians with robust product experience, our support team is ready to tackle your equipment concerns.

Consultation

Leave your info and we will contact you