Comprehensive Solutions for SMT Feeder Sales, Repairs, and Calibration Services: Enhancing SMT Efficiency

In the highly specialized field of Surface Mount Technology (SMT), ensuring the optimal performance of feeders is crucial for achieving efficient, high-precision production. This article provides an in-depth look into our expertise in the sales, purchase, repair, and calibration of Siemens ASM SIPLACE D, S, and X series feeders, offering a full range of technical services for your SMT needs.

The Role of Feeders in SMT Systems

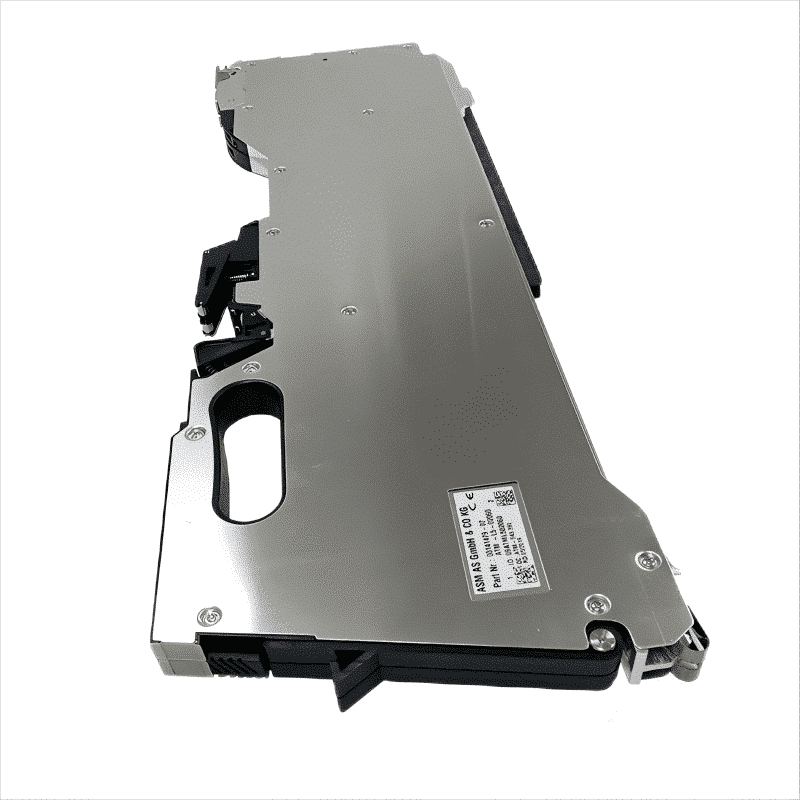

Feeders are essential components in SMT production lines, responsible for precisely delivering surface-mounted devices (SMDs) to pick-and-place machines. Our company specializes in supporting Siemens ASM SIPLACE feeders, offering sales, repairs, and calibration services to maintain seamless SMT operations.

Wide Selection of Siemens ASM SIPLACE Feeders for Various Applications

We provide a comprehensive range of Siemens ASM SIPLACE feeders designed for diverse production needs. Whether you require solutions for high-speed manufacturing or intricate assembly lines, our product line can accommodate your specific requirements.

Siemens D and S Series Feeders

Our Siemens D and S series feeders are available in the following specifications:

| Feeder Model | Size Specification | Application |

|---|---|---|

| 3x8SL | Small size | High-precision, small-scale production lines |

| 3×8 Gold/Silver | Standard size | Medium-scale production requiring versatility |

| 12/16mm | Medium size | High-speed production lines with moderate demands |

| 24/32mm, 44mm, 56mm | Large size | High-volume production requiring large components |

Siemens X Series Feeders

The Siemens X series feeders offer advanced solutions for high-precision, high-speed SMT production. Available models include:

- 4mm, 8mm single card, 2x8mm dual card

- 12mm, 16mm, 24mm, 32mm, 44mm, 56mm, 72mm, 88mm

These feeders are designed to meet the demands of cutting-edge SMT manufacturing environments.

Professional Repair and Calibration Services

To maintain the efficiency and precision of your SMT feeders, regular repair and calibration are essential. Our skilled technicians undergo rigorous training to ensure the highest standards of repair and calibration for Siemens ASM SIPLACE feeders. This attention to detail guarantees that your equipment remains in optimal working condition, minimizing downtime and maximizing production efficiency.

Importance of Calibration

Regular calibration is crucial for feeder performance, ensuring accurate component placement and preventing costly production errors. Our calibration services adhere to stringent industry standards, extending the lifespan of your feeders and reducing the risk of malfunction.

Advantages of Partnering with Us

Choosing a reliable partner for your SMT feeder needs is essential for long-term success in electronics manufacturing. Our company is dedicated to offering:

- High-quality used SMT feeders: We provide fully inspected and refurbished Siemens ASM SIPLACE feeders at competitive prices.

- Comprehensive after-sales service: Our support doesn’t end with the sale; we provide ongoing maintenance, repair, and technical assistance.

- Expert technical support: Our team is composed of seasoned professionals with extensive knowledge of SMT systems.

- Competitive pricing: Our pricing model is designed to offer maximum value without compromising quality.

Contact Us for Further Assistance

If you’re seeking high-quality used SMT feeders or need repair and calibration services for your existing equipment, don’t hesitate to reach out. We are committed to supporting your production goals and helping you maintain the highest levels of SMT performance.

Long-Term Supply of Siemens SMT Machine Spare Parts:

| PART NO | NAME OF PARTS |

|---|---|

| 00116113S01 | Set placement head nozzle sleeves |

| 00318002S01 | IC-vacuum nozzle magazine complete |

| 00319420S03 | Vacuum nozzle D=1,5 |

| 00319423S02 | VACUUM NOZZLE |

| 00321854-08 | NOZZLE TYPE 711 911 |

| 00321861-08 | NOZZLE TYPE 714 914 |

| 00321862-07 | VACUUM NOZZLE TYPE 715 915 VECTRA C130 |

| 00321867-07 | VACUUM NOZZLE TYPE 719 919 |

| 00322544-03 | NOZZLE 12,5mm, 418 NEW, COMPLETE |

| 00322546-03 | NOZZLE Typ 419 COMPLETE |

| 00322591-06 | NOZZLE TYPE 737 937 |

| 00322592-05 | NOZZLE Type 738-938 |

| 00322593-05 | NOZZLE TYPE 739-939 |

| 00322603-06 | nozzle type 701 901 Vectra-Keramik |

| PART NO | NAME OF PARTS |

|---|---|

| 00323044-05 | NOZZLE MAGAZINE 7xx 9xx |

| 00324996-07 | VACUUM NOZZLE TYPE 723 923 VECTRA A230 |

| 00325970-08 | NOZZLE TYPE 721 921 COMPLETE |

| 00325972-10 | nozzle type 720 920 cpl |

| 00327810-08 | NOZZLE TYPE 734 934 |

| 00328661-02 | NOZZLE 4xx TYPE 417 SHORTED |

| 00328843S03 | NOZZLE MAGAZINE FOR NOZZLE TYPE 7xx |

| 00330027-06 | NOZZLE ADAPTER 4xx to 7xx 9xx |

| 00330538-06 | NOZZLE TYPE 756 956 COMPL |

| 00333652-07 | nozzle type 725 925 Vectra-Ceramic |

| 00341091S01 | REJECT DEVICE NOZZLE CHANGER S50 |

| 00344764-02 | NOZZLE REJECT-BOX |

| 00345031-05 | NOZZLE Type 706 906 Vectra-Ceramic |

| 00346522-05 | NOZZLE TYPE 732 932 |

| 00346523-03 | NOZZLE TYPE 733 933 |

| 00346524-03 | NOZZLE TYPE 735 935 |

| 00348186-03 | NOZZLE Type 702 902 Vectra-Ceramic |

| 03011583-02 | NOZZLE ADAPTER COMPL. STANDARD SEAL |

| 03012036-01 | NOZZLE TYPE 516 complete Twin-Head |

| 03012042-01 | NOZZLE TYPE 517 complete Twin-Head |

| 03015840-03 | nozzle type 1004 cpl. ceramic |

| 03015854-02 | Nozzle Typ 1006 kpl |

| 03015869-03 | NOZZLE TYPE 1003 cpl.-0,9×0,5 |

| 03054153-03 | Nozzle-2003 cpl |

| 03054915-03 | Nozzle-2004 cpl |

| 03054923-02 | Nozzle-2033 cpl |

| 03056002-02 | Nozzle- 2020 cpl |

| 03056837-03 | Nozzle- 2820 cpl |

| 03057033-03 | Nozzle- 2037cpl |

[wpforms id=”1144″]