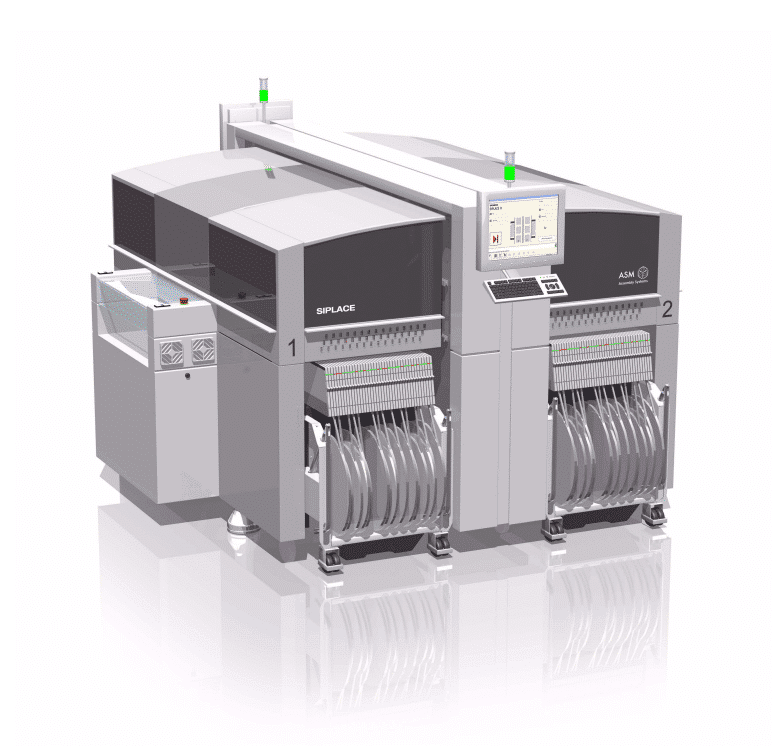

High-Quality Used SMT Equipment, Top Brands & Models

Looking to boost your SMT production? We’ve got you covered with a wide selection of quality pre-owned equipment. Our team is here to help you find the perfect fit for your business, big or small.

Reduce Your Capital Investment and Increase Productivity with Used SMT Equipment!

Wide Range of Brands We Support

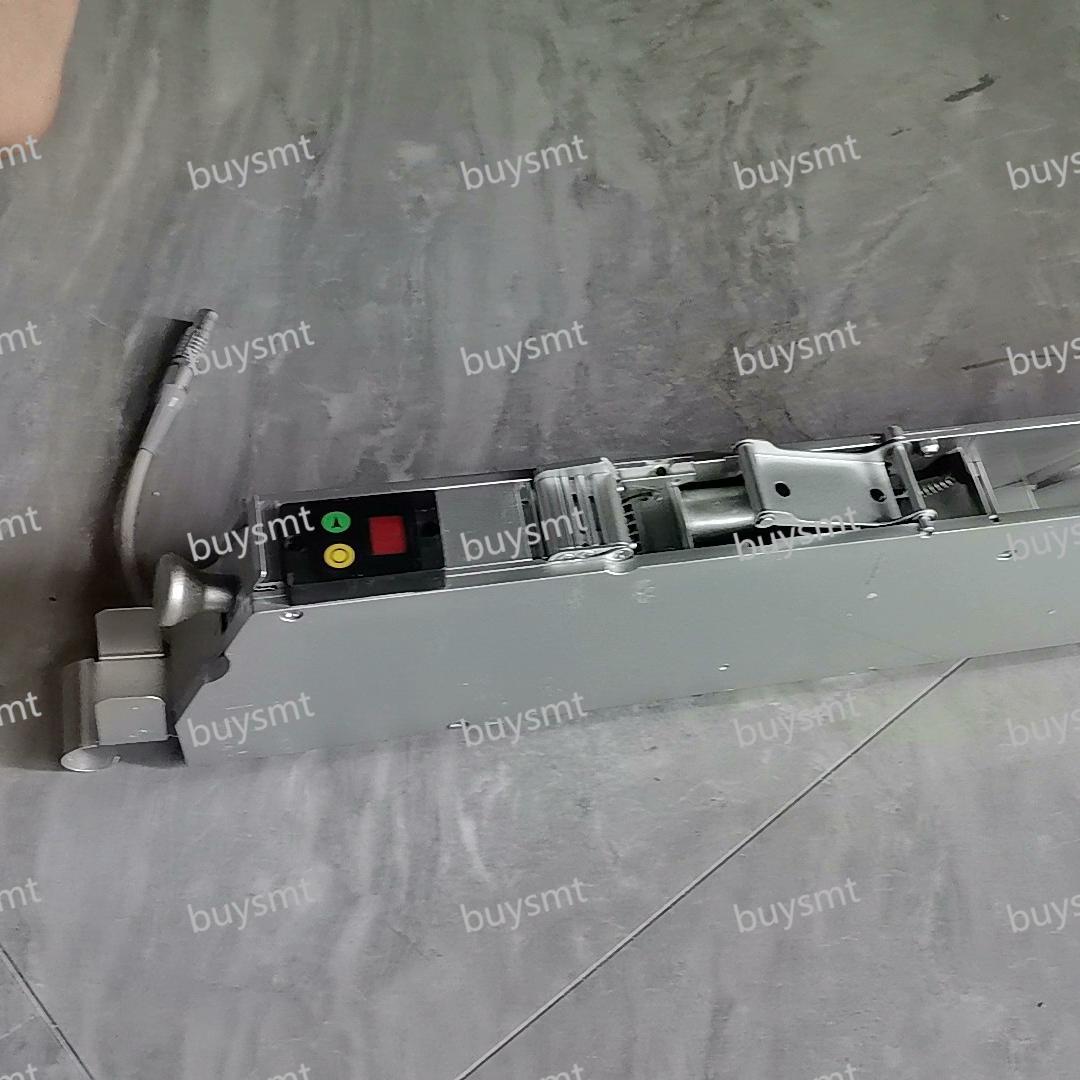

From SMT pick and place machines to PCB conveyors, we have an inventory of SMT machines and parts from famous brands that are compatible with numerous production lines. With products from FUJI, Panasonic, Yamaha, JUKI, and more, you can find the right SMT products for your facility right here.

Check out latest products

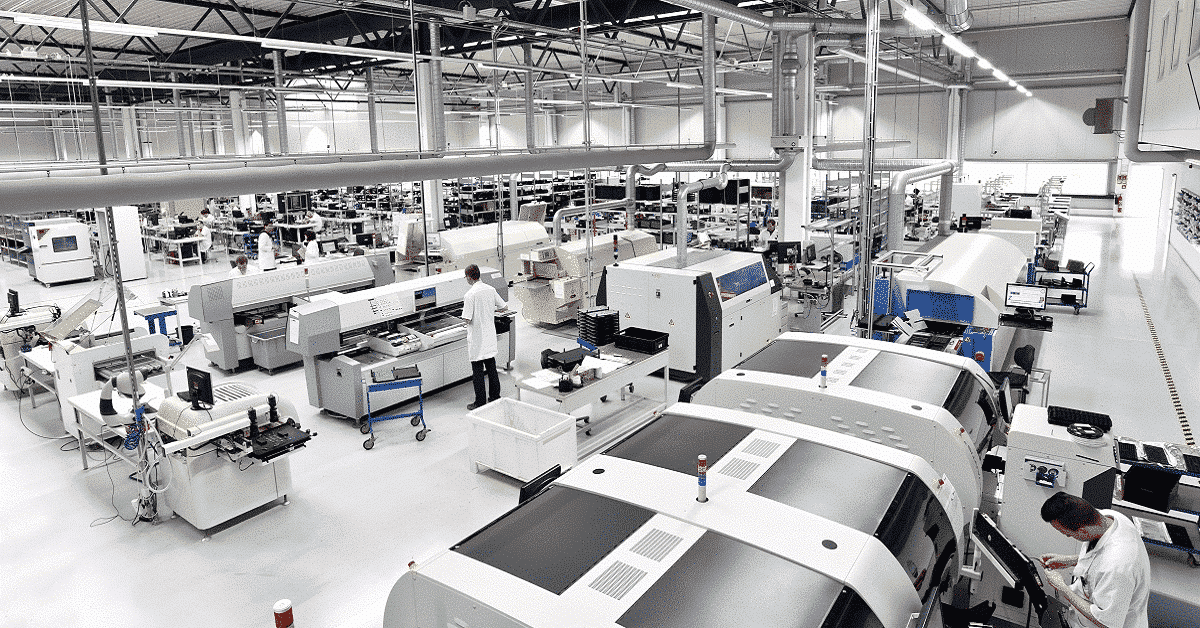

Your Total SMT Equipment Supplier

Your reliable partner for

used SMT machines

BUYSMT:

Purchasing SMT Product Has Never Been this Easy

We offer a wide range of used SMT equipment from top brands, including high-speed pick-and-place machines, printers, and reflow ovens. Our equipment is thoroughly inspected and refurbished to ensure optimal performance and reliability, meeting the demands of high-volume production.

When you purchase used SMT equipment from us, you can rest assured that you’re backed by our comprehensive after-sales service and technical support.

Quality Assurance

What You Need To Know About Our Company

As a trusted partner to the global electronics manufacturing industry since 2006, BUYSMT offers a wide range of SMT equipment and components. Our commitment to quality, reliability, and customer satisfaction has enabled us to build strong relationships with customers around the world.

Drop Shipping Service

Enjoy fast purchasing with guaranteed safe and quick deliveries with our partner logistics companies bringing your products directly to your doorstep.

Product Finding

Machine Maintenance

You can rest assured about after-sales problems as we offer preventive maintenance services on the SMT machines upon request.

Explore Buysmt

Technical Support

Equipped with expert technicians with robust product experience, our support team is ready to tackle your equipment concerns.

Get Expert Help

Read the latest