Basic Info.

Model NO.

TP400V

Precision

High Precision

Certification

ISO, CE

Warranty

18 Months

Automatic Grade

Automatic

Type

High-speed Chip Mounter

Accuracy

0.05mm

Max PCB Size

400*350mm

Placing Speed

3500cph

Max Printing Size

400*350mm

Max Moving Range

400*630mm

Z Axis Max Moving Range

70mm

Typical Mounting Speed

2000-2800cph

Power Supply

220V, 50Hz, 3kw

Mounting Accuracy

+/-0.05mm

Weight

310kg

Transport Package

1100*960*750mm

Specification

CE

Trademark

TERMWAY

Origin

China

HS Code

8479896200

Production Capacity

20 Sets Per Month

Packaging & Delivery

Package Size

128.00cm * 141.00cm * 75.00cm

Package Gross Weight

410.000kg

Product Description

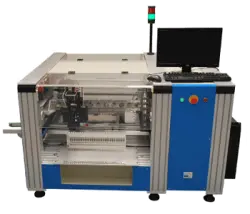

Automatic visonal high speed Pick and Place Machine TP400VII (0402 and above)

Introduction:

Automatic pick and place machine TP400V-11 is the high cost-effective equipment in the market, it can pick and place variety of components by its vacuum nozzle. The machine can mount SMD chip components above 0402,SOIC, PLCC, QFP IC; vision position system which can meet pitch 0.5mm of QFP IC. Beside round datum mark,square PCB pad and ring hole pad can be recognized as datum mark.

Features::

1. Automatic Mount by control of software.

2. Quick PROTEL data import or write-in by hand

3. Visional + machinery position.

4. Visional program system can identify MARK point automatically to improve production efficiency and accuracy.

5. Visional program system can produce X, Y coordinates of all components automatically after confirmed the basic MARK point, and them complete the mounting process.

6. Unique optical prism and high-definition industrial cameras for placing high-precision components.

7. Exact quadrate guide rail, smooth gliding arm for improving mounting accuracy.

8. Air suspended pick-and -place head

9. Automatic nozzle replacement system.

Main parts: :

1,DC servo motor driving system

It uses loop DC servo motor driving system for a high precision repeating accuracy and stability.

2,Vision centering system

Vision centering system can mount 0.5mm pitch QFP IC

3,No-contact flying centering system

Flying centering system can mount most of SMD components include: 0402, SOIC,PLCC & QFP IC.

4,Flexible reference point system(RPS):

In addition to standard Round reference point, square PCB pad and ring PCB pad with hole also can be identified as a reference point.

5,All-purpose automatic feeder

TP400V-ii has 8mm, 12mm,16mm, 24mm , you can choose to install according to your component type and your required speed.

6,Flexible tray-type station

TP400V can equip 2 tray which is help mount bulk components under the semi-auto mode.

7,CAD/Protel data transfer Except for study the component coordinate by Camera or keyboards input, you can choose CAD transfer software WCAD (optional) to transfer the PCB’s CAD into pick and place data.

8,Buffering nozzle

Buffering nozzle can adjust the pressure automatically according to different components height to avoid the damage due to different component heights or programming errors, it is suitable for various types of pick and place ceramic components and ceramic circuit board.

Technical Parameter:

Optional:

1. Automatic feeder

2. IC disc

3. Automatic PCB transmission system