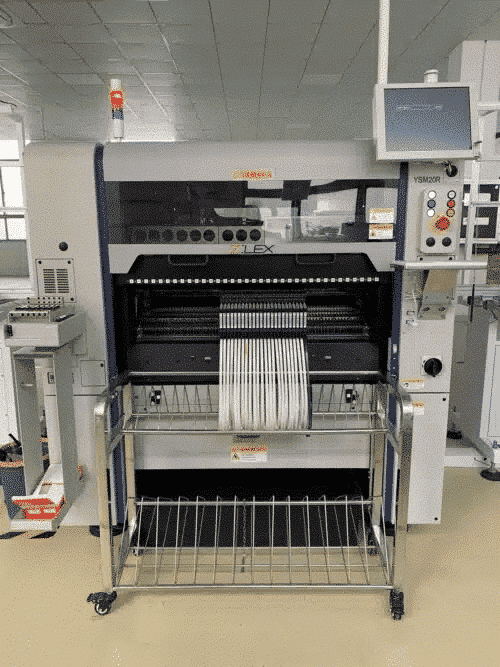

In the quest to enhance production efficiency, investing in a high-quality used pick and place machine can be a transformative decision for manufacturers. These advanced machines automate the meticulous task of picking components and accurately placing them onto printed circuit boards (PCBs) or other substrates, thereby streamlining assembly processes. This guide delves into the essential aspects of selecting a used pick and place machine, exploring their advantages, critical features, and considerations for seamless integration into your production workflow.

Understanding the Benefits of Pick and Place Machines

Pick and place machines play a crucial role in modern manufacturing, offering numerous benefits that significantly enhance productivity. Here are some key advantages:

- Increased Efficiency: Automation reduces the time required for component placement, allowing for higher throughput. By optimizing the speed and precision of assembly processes, manufacturers can significantly boost their output without sacrificing quality.

- Enhanced Accuracy: These machines provide precise placement, minimizing errors and improving product quality. The accuracy of component placement directly impacts the reliability of the final product, making this a vital consideration for manufacturers.

- Labor Cost Reduction: By automating repetitive tasks, companies can optimize labor resources and focus on more complex operations. This not only leads to cost savings but also allows for a more skilled workforce to be employed in areas that require critical thinking and problem-solving.

Essential Features of Used Pick and Place Machines

When considering a used pick and place machine, it is vital to evaluate specific features that align with your production requirements. Key aspects to consider include:

| Feature | Importance |

|---|---|

| Placement Speed | Determines the number of components placed per hour, impacting overall output. Machines that can achieve higher placement speeds are essential for high-volume production lines. |

| Accuracy | Measured in microns; higher accuracy leads to better quality control. Machines with lower placement tolerances ensure that components are correctly aligned and securely mounted. |

| Feeder Types | Compatibility with various feeder systems for different components. A machine that supports multiple feeder types offers flexibility in handling diverse product lines. |

| PCB Size Compatibility | Ability to accommodate varying PCB sizes, allowing flexibility in production. Ensure that the machine can handle both standard and custom PCB dimensions. |

| Software Integration | Compatibility with existing software systems for streamlined operations. Machines that can integrate with CAD/CAM software and other production management tools enhance overall efficiency. |

Key Considerations for Selecting a Used Machine

Choosing the right used pick and place machine involves careful consideration of several factors:

Assessing Machine Condition

Evaluate the physical and operational condition of the machine. Request detailed maintenance records and inspect for wear and tear. Machines with a robust service history are likely to provide reliable performance. Pay attention to components such as the vision system, mechanical parts, and electronics, as these are critical to the machine’s operation.

Vendor Reputation

Purchase from reputable vendors who offer transparency regarding the machine’s operational history. Reliable vendors should provide after-sales support, including maintenance services and training for your staff. Research the vendor’s track record in the industry and read reviews from other customers to gauge their reliability.

Software Compatibility

Ensure that the used machine’s software can integrate seamlessly with your existing systems. This integration is crucial for maximizing efficiency and ensuring smooth operations. Look for machines that are compatible with the latest software versions, allowing for future upgrades as technology advances.

Return on Investment (ROI)

Calculate the potential return on investment by considering factors such as increased production capacity, labor savings, and improved quality. A thorough analysis will help justify the purchase of the machine and ensure that it aligns with your business goals.

Making the Purchase Decision

After assessing the features, condition, and vendor reputation, it’s time to make the purchase decision. Here are steps to facilitate a smooth transaction:

- Conduct a Final Inspection: If possible, visit the vendor’s facility to inspect the machine in person. This step can provide valuable insights into its operational capabilities and overall condition.

- Negotiate the Price: Don’t hesitate to negotiate the price based on the machine’s condition and market value. Research similar machines to ensure you are getting a fair deal.

- Request Warranty and Support: Inquire about any warranty or support options available. A warranty can provide peace of mind and protect your investment.

- Plan for Installation: Consider the logistics of machine installation and training for your staff. Proper installation is critical for ensuring optimal performance.

Conclusion

Investing in a used pick and place machine can greatly enhance your production capabilities. By focusing on the benefits, essential features, and key considerations outlined in this guide, manufacturers can make informed decisions that align with their operational needs and budget constraints. The right machine will not only improve efficiency but also contribute to the overall quality and reliability of the manufacturing process. With a strategic approach to purchasing, companies can successfully integrate used equipment into their production lines, paving the way for innovation and growth in a competitive market.