What is an SMT Machine?

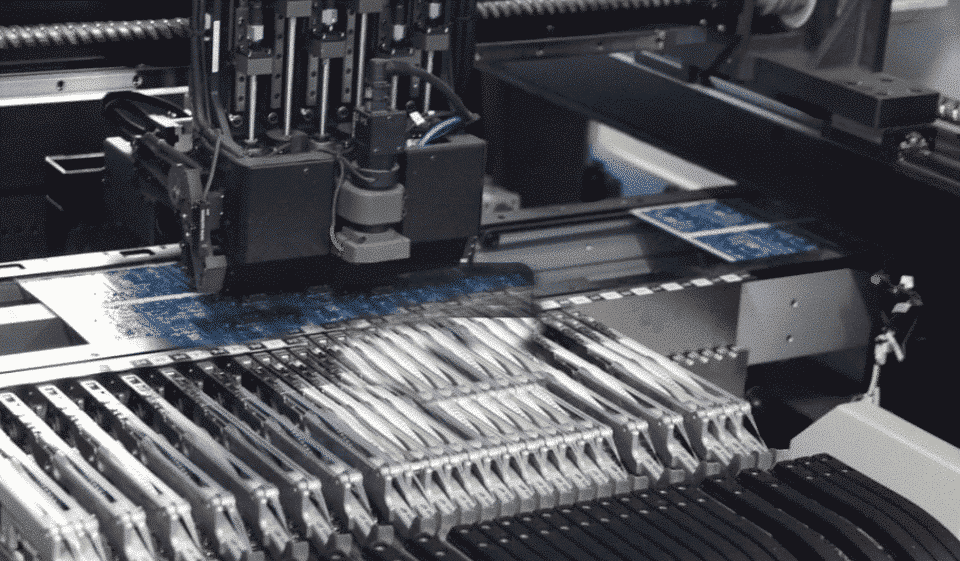

SMT stands for Surface Mount Technology. An SMT machine is a piece of automated equipment used to place electronic components, such as LEDs, onto a printed circuit board (PCB). Think of it as a highly precise robot that can pick up tiny components and position them accurately on a circuit board.

Why Do LED Production Lines Need SMT Machines?

- Efficiency: SMT machines automate the placement process, significantly increasing production speed.

- Precision: They place components with extreme accuracy, ensuring high-quality products.

- Flexibility: SMT machines can be configured to handle a wide variety of components and board sizes.

How to Choose the Right SMT Machine

- Define Your Production Needs:

- Product Type: What kind of LED products are you producing? Simple single-color LEDs or complex RGB lights?

- Production Volume: How many units do you plan to produce daily, weekly, or monthly?

- Precision Requirements: How accurate do you need the placement to be?

- Understand the Components of an SMT Machine:

- Pick and Place Machine: This is the core component that picks up and places components.

- Printer: Applies solder paste to the PCB.

- Reflow Oven: Heats the PCB to melt the solder and create a connection.

- AOI Inspection: Inspects the PCB for defects.

- Select a Reliable Supplier:

- Brand Reputation: Choose a well-known brand for better quality assurance.

- After-sales Service: Ensure the supplier provides good after-sales support.

- Cost-effectiveness: Consider the price and performance of the machine.

Key Considerations When Choosing an SMT Machine

- Compatibility: Ensure the machine can handle the components and PCBs you use.

- Maintenance Costs: Factor in the cost of maintenance and spare parts.

- Technical Support: The supplier should provide adequate technical support.

Tips for Beginners

- Learn the Basics: Research SMT technology and equipment to gain a basic understanding.

- Consult Experts: Seek advice from SMT equipment suppliers or industry professionals.

- Visit Factories: If possible, visit factories to see SMT machines in action.

Summary

Choosing the right SMT machine for your LED production line is a significant decision. By carefully considering your production needs and the factors discussed above, you can select a machine that meets your specific requirements.

Remember: SMT equipment is a significant investment, so it’s important to do your research and choose a machine that will serve you well for years to come.